Sacaramento pit

Gloryholes

Sacramento hill

Sac Hill

Sac Pit

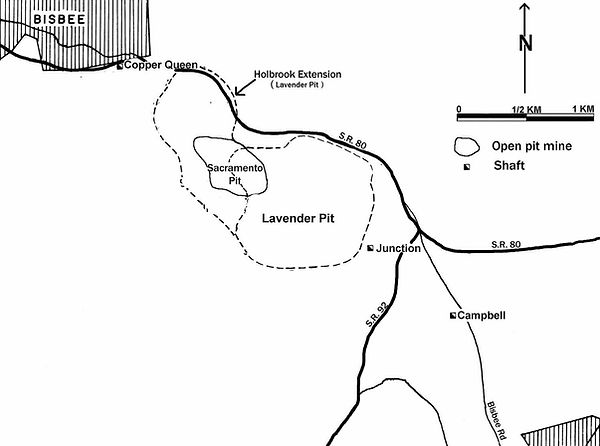

In 1909, exploration began on the Sacramento Porphyry. After an intensive search by underground workings and by churn drilling from the surface two separate orebodies were delineated, the East and West Ore Bodies. The West orebody was of higher grade, but the ores from both would be required to be processed by a concentrator regardless of the mining method chosen. To be profitable, the mining method would need to move large tonnages quickly at a low cost. The three alternatives considered were open pit mining with steam shovels, underground block caving, and underground top slicing. Block caving was quickly eliminated. The advantage of top slicing was that the waste rock covering the ore could remain and not have to be mined. On the other hand, underground mining would restrict the tonnages mined to available mine car size and hoisting capacity. Underground mining was considered more dangerous and skilled miners are always a challenge to acquire. The open pit would require mining millions of tons of waste for at least two years before any significant ore would be mined. Also, a heavy investment in machinery would be needed. Finally, it was hoped that the mine would be safer than underground and for many of the positions less skilled labor could be hired. As the estimated cost were roughly the same, the difficulty in hiring skilled miners swayed the decision and it was decided to develop an open pit mine, Yet, just before this decision and area was being prepared to be stoped and was closed after the decision to start an open pit. The pit would use rail for haulage and with 20 and 25 -ton rail cars which would be loaded with steam shovels. On April 5, 1917, stripping began with one steam shovel operating. On June 6, 1918 the peak was blasted from Sacramento Hill. Phelps Dodge had hired some experienced open pit miners largely from the Chino Pit at Santa Rita, New Mexico, but others had come from the Iron Range. Yet, with the United States being drawn in to World War I hiring quality staff was difficult. Blasting became a problem. At the time a Bisbee miner was reported at the time, as saying in reference to blasting on Sacramento Hill, “Powder is the most uncertain thing in the world, except a woman”. After the first three years of Sacramento Pit operating, he may have removed the exception. Fly rock from the blast initially, caused the most problems. The town of Jiggerville, roads and mine buildings were regularly pummeled by flying rocks People we warned by Phelps Dodge to keep off all roads and trails from west end of Sacramento Hill and Gardner Shaft. Also, they wanted all people to keep clear of the area from the Copper Queen machine shop to the Sacramento Shaft unless, they were an employee or on urgent business. The company guarded area during large blasts When the miners were blasting boulders in the pit they stated areas may not be guarded, but people should listen for blasting signals, locomotive whistles and shovel whistles giving seven short blows. The company was particularly concerned about, visitors and sightseers in particular. In 1918, the Copper Queen Safety build had to be abandoned because it location was too dangerous. The building was too close to the pit. A new safety building was constructed at the Czar Mine. For the blast on May 31, 1917, Phelps Dodge asked residents of Naco road to temporarily evacuate as the 6,000-7,000 lbs. of explosive were detonated. Windows were regularly broken and plaster in buildings was knocked down, but this was more of an inconvenience and then a danger, unlike fly rock which injured residents and killed a miner. Great tragedy occurred with premature blasts. In 1918, eight men were killed from early detonations. With most of these accidents it remained unclear of the cause of the detonation, but conditions improved rapidly. During 1919, no one was killed working in the Sacramento Pit and only two more men were killed in premature explosions until the final closure of the pit. To help aid in blasting, the speeds each blast hole was drilled was monitored to determine the properties of the rock. This gave the crews a better idea on how much explosive was needed in each hole. Small, steel, blasting, shelters were soon placed around the mine site. A bilingual Mexican, was added to the safety department to ensure that the safety could be readily understood by Spanish speaking workers of Phelps Dodge. The steam locomotives and shovels needed water. Originally, water from Naco, Arizona was tried, but the water did not effectively soften. Instead the water for the Sacramento Pit was from the Junction Mine. A water softening plant was constructed and provided between 100,000 and 180,000 gallons of softened water per day. At the end of World War I, the copper market fell compiled with delays in the construction of the concentrator resulted in all stripping operations to be stopped in the pit in 1921. The main orebody was uncovered in June 1921 and soon all work was stopped in the pit except the mining of 4,000 tons a month to be used as a silica –rich flux at the Douglas Smelter. In 1922, the Calumet & Cochise Shaft finally, encountered enough clean water to provide water for the concentrator and the Sacramento Pit. During December, the steam shovels were being overhauled to begin mining again. From April 1922 until 1929, the Sacramento Pit mined continuously. Slowly, the rails spiraled on a gentle 2 ½ % grade towards the bottom. The last 130-145 ft. of ore was mined through “Glory Holes” eleven, ten foot by ten foot raises were driven into the bottom of the Sacramento pit from the 400 level of the Sacramento Mine. At the 400 level were “bulldozing” chambers with grizzlies covering raises to the 500 level for haulage. Getting as close to the edge of the raises as was safe, churn drills drilled 60 foot holes that were blasted with 400-500 lbs. of explosive. An adit from the 200 level of the nearby Holbrook mine was used to deliver explosives and drill steel to the top of the glory holes. Once at the bottom of the pit, burros (not mules) were used to deliver the supplies. Interestingly, water seeping down the pit was captured in a water ditch that was direct into this adit to be pumped from the Holbrook Shaft. These along with jackhammers and Leyner drills mounted on tripods, miners carved out a conical pit that included the raise. The blasted rock would fall down the raise to the grizzlies in the bulldozing chamber. Boulders too large for the haulage level chutes would be caught on the grizzlies and were re-blasted or broken with a sledge hammer. From the grizzlies it would fall into storage chutes on the 500 level to await haulage. This ore was hauled in 4-ton gable bottom “Koppel” style mine cars to the ore. The glory hole mining continued until 1931 when the West Orebody was depleted. The Sacramento Pit had mined from 5,665 ft. elevation down to 4,925 ft. elevation. The pit presented a hole at the 5,360 ft. elevation that was 1,400 ft. by 1,200 ft. The monstrous, mechanical, machines had moved 11,200,000 tons of waste rock, 12,600,000 tons of low grade leach material and including the gloryhole operation, 7,957,370 tons of ore. A total of 358,144,662 pounds of copper, 1,365,191 ounces of silver and 54,234 ounces of gold were directly produced from the operation. Leaching of the low grade ores produced a further 57,220,648 lbs. of copper, but this leaching continue off and on until 1944. This engineering marvel of the time began a popular site for area tourists to visit until the time it was backfilled by mining operations from the newer Lavender Pit. Then in 1965, it was decided to expand the Lavender Pit into the Holbrook Mine region. Operations from the Lavender pit mined through the older Sacramento Pit removing the back fill and nearly all of the Sacramento Pit. In the early years the Sacramento open pit was the West Orebody or called simply “Sacramento Hill” after a true pit began to develop when the benches dropped below the 5,360 elevation, it tended to be called the “Sac” Pit and during the last couple years it was referred to as the plural “Glory Holes” This should not be confused with the original open cut of the Copper Queen Mine which is called the singular “Glory Hole.”

References

“ Concentrator May Soon Be Erected in Warren District.” Bisbee Daily Review 3 September 1916, page 9

“ Watch Your Step While in Vicinity of Sacramento Hill” Bisbee Daily Review 25 April 1917, page 3

“ Monster Blast will Shake Sacramento Friday Afternoon” Bisbee Daily Review 31 May 1917, page 2

“ Doing Considerable Damage” Bisbee Daily Review 25 November 1917, page 7

“ Public Warned not to Visit Scene of Shovel Operations” Bisbee Daily Review 30 December 1917, page 1

“ Gigantic Charge takes Peak from Sacramento Hill” Bisbee Daily Review 7 June 1918, page 3

“Sacramento to Furnish Waste for Many fills” Bisbee Daily Review 7 June 1918, page 9

“Breaks Record on Sacramento Hill” Bisbee Daily Review 12 January 1919, page 9

“ Records are Broken on Sacramento Hill” Bisbee Daily Review 9 February 1919, page 6

“Victory Loan workers meet Friday Night” Bisbee Daily Review 24 April 1919, page 8

“ Sacramento Park Future Suburb” Bisbee Daily Review 4 May 1919, page 9

“Whippet Tank Says Goodbye to Bisbee in Tombstone Next” Bisbee Daily Review 2 May 1919, page 6

“Mining Notes” Bisbee Daily Review 6 July1919, page 10

“Problems in the Gigantic Task of Leveling Sacramento Hill” Bisbee Daily Review 27 July1919, page 8

“Safety First” Bisbee Daily Review 2 November1919, page 8

“General Manager, G.H. Dowell of Copper Queen Branch Explains Reasons Found Necessary For Laying off Men on the Hill” Bisbee Daily Review 2 November1919, page 8

Location of the Sacramento pit (almost entirely mined out) to the Lavender pit

Sacramento pit showing the glory holes at the bottom of the pit and a abandoned shovel (center of photo). Circa 1940

New York public library photo

Sacramento pit looking towards Bisbee. Note large amount of timber from underground mine workings cut by the pit. Circa 1940

New York public library photo