Powder car

Powder car inside The Queen mine tour

Transporting explosives in the underground mines was done with specially designed powder cars, fuse cans and powder sacks. The powdered cars are constructed with steel wheels and frame, the box being made of wood. The inside of the car is rubber lined to prevent sparks and static electricity. The outside of the car is painted bright red and marked in white explosives. Fuse cans are made of red painted heavy gauge galvanized steel with a rubber lining inside. Powder sacks were made of heavy treated canvas

Powder cars where use to transfer explosives from the surface to the underground powder and cap magazines. The procedure in transporting explosives in the 1950’s, 60’s and 70’s was to start with a delivery of explosives to the Junctions mine yard. Carbamite came in 50lb sacks and dynamite in 50lb boxes, these would be transferred into small trucks marked with red flags, which delivered the explosives to the individual mines. Blasting caps and fuse rolls went directly to the fuse house on the surface. Here the fuses were capped and cut to length before being delivered underground.

Damaged Powder Car Junction Mine 1966

At the mines the dynamite and/or Carbamite would be loaded into the powder cars from the trucks. The cars then would be transferred to the awaiting cager at the shaft collar. At this time all other hoisting operations will cease until the entire amount of explosive are underground. Below at the station which the explosives are headed, another cager awaits with the powderman and assistant to receive them. The surface cager will load the cage, without using landing chairs, and secure car by closing cage bar and gate. When lowering no men or materials are allowed on the cage and no mixing of detonators with high explosives, they will be lowered in separate trips. At the station the cager will unload the explosives without using the landing chairs and turn the explosives over to the powderman. The cager will proceed to the next station to which explosives are to be delivered, repeating this until the task is finished. The powder car will be taken to the powder magazine with a motor or hand trammed. When hand tramming the powderman will precede the car to safeguard its passage, throw track switches, open air doors. At all times the powder car will have the right of way. If motorized haulage is done the car must be connected with and insulated drawbar and the car is to be pulled not pushed. The train will only consist of powder cars no other types of cars are allowed. The powder man will only proceed the train if other motors are running in area. The train will travel at a slow rate of speed to the magazine, again they will be given the right of way.

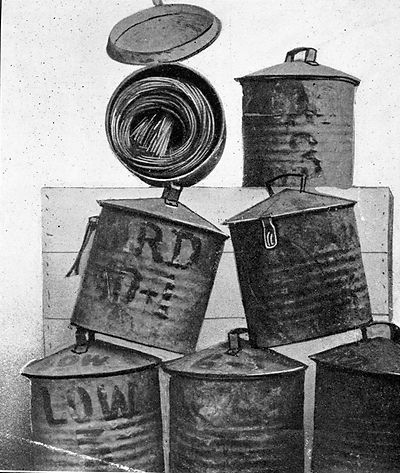

Fuse can

In beginning in the 1940’s early 50’s Bisbee mines precut their fuses to length and fitted them with blasting caps before sending them underground. To transport the fused caps were coiled inside the fuse cans. Then the cans could be loaded inside the cage, powder cars or hand carried. The safety rules are similar to that of high explosives in that blasting caps ride in the cage alone and a person has to walk ahead of transported caps when they are moved from the station to the magazine. Fuse cans on occasion were used to carry dynamite like in the transportation up service raises on the way to magazines.

Miner hanging up empty powder sacks Junction mine circa 1940’s

Powder sacks were used to transport the dynamite and caps from the magazines to the miner’s work place. The explosives could be carried by the same person together except they had to be in separate sacks. These sacks were custom made in the rope shop and were used for various other uses.

Sign indicating were to hang empty powder sacks

Miners loading round with powder sacks on ground circa 1940’s

Stack of fuse cans used in the Sacramento Pit circa 1920’s

Green rubber lining inside a powder car

End of powder car showing end markings

References

Code of Safe Practice for Transporting Explosives and Underground Magazines 1972, Phelps Dodge Corporation pp.1-3

Henry Hernandez 2010, pers. comm., March

Richard Graeme IV 2010, pers. comm., 8 March

Richard Graeme III 2010, pers. comm., 13 March

Pete Oller 2010, pers. Comm., March

Procedure of Safe Practice for Transporting Explosives From Shaft Collar to Underground Magazines Operation Of Magazines, and issuing explosives 1949, Phelps Dodge Corporation pp.1-13